Profile projectors are versatile tools that provide a visual representation of a part’s dimensions and surface characteristics. They help ensure that manufactured components meet the required specifications, thereby enhancing quality control and minimising production errors. Newer versions of these instruments are available with full digital imaging and part recognition which further enhance their capabilities.

The projectors are used for quality control and inspection processes in manufacturing, but what features do these machines offer and are they being used to their full advantage?

Dimensional Inspection: profile projectors are commonly used to measure and inspect the dimensions of manufactured parts. The projector can display a magnified image of the part on a screen or a digital display. By superimposing a profile template or a CAD drawing onto the projected image, operators can compare the actual profile of the part with the desired specifications. This allows them to check for any deviations or errors in the manufacturing process.

Surface Inspection: an image of the part is projected onto a screen, allowing operators to analyse the surface for defects such as scratches, dents, or imperfections that may affect the product’s quality or functionality.

Form and contour measurement: by rotating the part on the projector’s stage, operators can capture multiple views and project them onto a screen for analysis.

Reverse engineering: in some cases, a manufacturing company may use a profile projector for reverse engineering purposes. By projecting the image of an existing part onto a screen, engineers can capture its dimensions and contours.

There are a wide range of profile projectors available on the market, floor-standing, bench-mounted, horizontal, side-bed, digital displays or manual overlays. The most common type are the horizontal versions which can be supplied for bench or floor mounting.

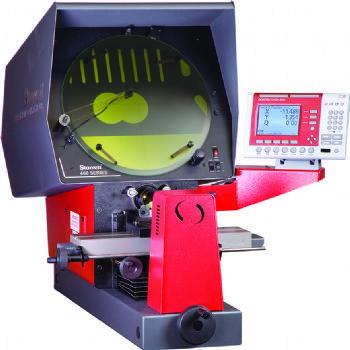

An entry-level version available from Market Harborough-based

Optimax IIM Ltd is the Starrett HE400 horizontal shadowgraph, a horizontal profile projector featuring a sturdy, metal construction, with LED surface and profile illumination which is also fitted with industry-leading ‘Quadra-Check’ or ‘Metlogix’ digital readout systems as standard. It is competitively priced and built to the same high mechanical standards as the full range of Starrett profile projectors for superb all-round capacity and performance.

Key features of this product include: fully usable 400mm dia screen with precision cross lines, overlay clips and integral hood; large measuring travel, X/Y travels of 254 x 100mm; high precision workstage with 480 x 120mm top plate with machined slot for easy fixturing; and 25kg stage weight capacity. Lenses are available from 10x-100x and lamphouse-mounted helix adjustment for accurate thread-form inspection.

The full range of Starrett Profile Projectors are available in the UK from

Optimax IIM Ltd.